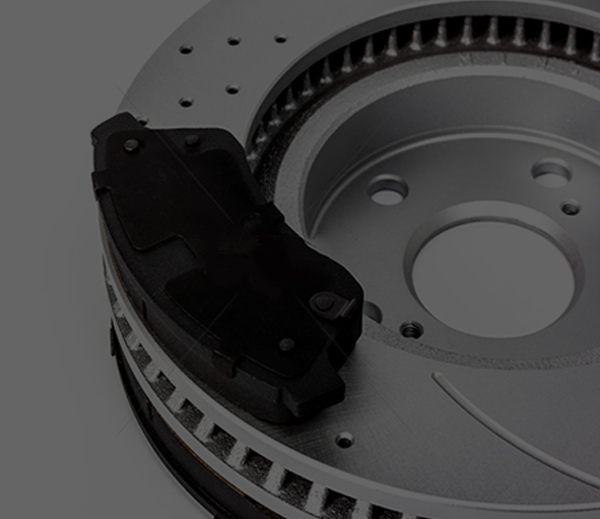

various bonding systems of the grinding wheels

In order to effectively grind a large range of materials, various bonding systems are used to hold the abrasive grits to the surface of the wheel. Resinoid, Vitrified, Metallic, and Electroplated bonds are mainly used.

Resin Bond

Resin bonds are manufactured with a mixture of measured amounts of phenolic or polyimid resin and filling agent. Phenolic resinoid bond is predominantly used at present, but polyimid bond is often used to increase wear resistance of the grinding wheels. Phenolic resin is used of DIAMOND / CBN grinding wheels for medium finish or finish grinding, and it shows various properties when mixed with organic or inorganic fillers. Resinoid bond wheels can be designed for both wet and dry grinding modes, shows good free cutting qualities.

Vitrified Bond

Vitrified bonds, also known as ceramic bonds, show higher bonding strength than resinoid bonds. Vitrified bond wheels which are good for free cutting, produce good surface roughness, have good wear resistance and retain straightness and form very well. The porosity(pores) or open structure of vitrified grinding wheels can be controlled to provide chip pocket, allow coolant in, and prevent wheel loading. Equipped with a roller diamond dresser,the vitrified bond wheels can be widely used in the automobile parts industry as well as bore processing of bearings.

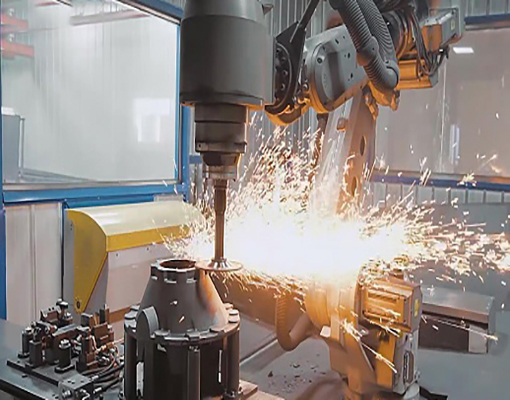

Metallic Bond

Metallic bonds are formed from compounds of various metal powders such as Cobalt, Copper, Brass, Iron, Tin, Nickel, Tungsten, Silver and so on. Through powder metallurgical method, metal bonded wheels are produced, which are recognized for excellent form-holding capabilities, high wear resistance and strength in structure. They are suitably used in such fields of industry as requiring high productivity with longer life of wheel for brittle materials (Glass, Ferite, Si, Ge,& Ceramics), high form retention for plunge, profile grinding & NC grinding machine and conductivity for electrolytic grinding. Furthermore, metal bond wheels are useful in the honing operation for ceramic and cast iron under low rpm because of their high wear resistance.

Electroplated Bond

Nickel is the most commonly-used-metal because it has good plating qualities and provides excellent bonding strength. This bonding process makes it relatively easy to produce wheels of any form or contour, depending on the shape and size of the steel core. This wheel shows such characteristics as highest stock removal capability, maximum abrasive particle exposure, and easily produce complex forms while consisting of a single layer of superabrasive particles bonded to the wheel surface. Electroplated bonds are especially useful for grinding deep forms such as gear teeth, splines and grooves, as well as eye-glasses and silicon wafer.

Zhongbang sales&technician team are always ready to help if our clients have any questions about choosing or purchasing the best grinding wheels.