-

About Us

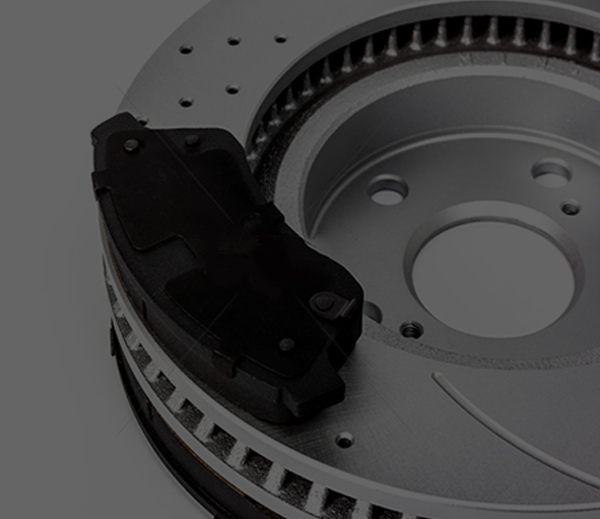

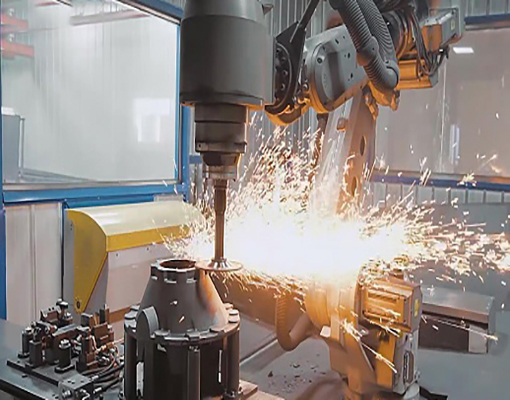

We are a private national high-tech enterprise, science and technology giant cultivation enterprise, specialization and special new enterprise. Member units of CFSMA, China Compressor Association, CMTBA, China Foundry Association, Mechanical Transmission Council、CCIA.The company has obtained 42 national patents, including 9 invention patents and 33 utility model patents. We focus on the R&D and production of superhard material grinding tools. We have established a complete production and quality management system.

- Products

-

Solutions

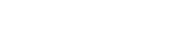

FULL HYDRAULIC STEERING STATOR Grinding ToolsCVT PULLEY GROOVE Grinding ToolsLEAD SCEW Grinding ToolsENGINE VALVE Grinding ToolsCOMPRESSOR SPRING Grinding WheelGEAR SHAFT Grinding ToolsCASTING Grinding ToolsCAMSHAFT Grinding ToolsCompressor Rotors Grinding WheelCompressor Groove Grinding Wheel

-

Resource

- Contact

Request A Quote