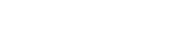

Electroplated Diamond Wheels Applications

Diamond electroplating grinding wheel is to electroplate diamond on the grinding wheel by electroplating. Diamond electroplating grinding wheel tool is a glass accessory suitable for grinding and chamfering of the opposite sex or size. After sanding, thickening and other steps, the diamond particles are fixed on the substrate to form a nickel-diamond composite coating with a sharp working surface, which has the advantages of strong bonding force, high grinding efficiency, and small shape error. Diamond electroplated grinding wheels are extremely hard materials and tools invented by human beings so far. Various hard new materials that emerge in an endless stream can only be processed with them. They provide strong support for the development of high-tech materials and various manufactured products. The development of the national economy has hundreds of times of leverage.

1. Optical glass industry

Using the electroplated diamond cutting knife, the round blanks of optical instrument lenses of various specifications can be directly removed from the optical glass plate. Compared with the old process of cutting into squares and then gradually processing into round blanks with diamond grinding wheels, this greatly saves raw materials, reduces procedures and improves work efficiency.

There are new mesh-shaped soft grinding discs made by electroplating in foreign countries. These electroplated diamond products, together with diamond cup grinding wheels, edging grinding wheels, diamond fine discs and other tools, realize the optical glass processing from blanking, cutting, grinding, Comprehensive innovation in a series of processes from edging to fine grinding and polishing of concave and convex surfaces.

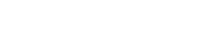

2. Mechanical processing industry

Electroplated diamond rollers have been successfully applied to dressing ordinary grinding wheels for profile grinding, or directly for profile grinding of workpieces. Form grinding is the direction of the development of grinding technology today. The application of electroplated diamond rollers has effectively promoted the development of the advanced technology of form grinding. Diamond rollers are now widely used in the processing of crankshafts, Bearings, hydraulic valves, racks, gears, shaft grooves, steering knuckles, worm gears, thread taps, piston ring grooves in cylinders, blade root grooves on steam and gas turbines, etc. Electroplated diamond grinding head is widely used in processing and grinding various shapes of surfaces and inner holes of molds or parts made of cemented carbide or hardened steel.

3. Electrical and Electronic Industry

Electroplated diamond inner circle and outer circle cutting slices are the best tools for cutting hard and brittle precious materials such as semiconductors, gemstones, and jade. Semiconductor materials such as single crystal silicon germanium require cutting and grinding. Use a wire saw The cutting method is not efficient, but the use of electroplated cutting blades for sawing not only has high efficiency, but also has a narrow kerf and less material loss.

4. Ferrite is the main material for making electronic components, and can be used as the magnetic head of magnetic tapes, tape recorders and data storage devices.

This material is suitable for cutting and profile grinding with electroplated diamond outer circular saw blades and electroplated diamond grinding wheels. Electroplated cutting wheels are also the most economical tool for cutting electrical insulating materials such as printed circuit boards and bakelite.

5. Graphite and carbon materials are hard and brittle. They cannot be rolled, drawn and sheared by conventional processing methods like metals, but they can be processed effectively with diamond electroplating tools.

For example, a large graphite block can be planed with an electroplated diamond grinding wheel, cut with an electroplated diamond saw blade, and shaped and ground with an electroplated diamond grinding wheel. Using various shapes of electroplating tools, various graphite components such as graphite molds and graphite electrodes of different shapes can be processed

6. High-efficiency and precise processing of single-product silicon wafers and polycrystalline silicon wafers, optical glass, grinding, etc., non-superhard material tools; micro-precision cutting, slotting, backside thinning, and nano-diamond processing of large-scale integrated circuits such as computer chips Polishing and other processing, non-superhard materials and tools; satellite solar panel processing, non-superhard material tools; no high-precision, high-efficiency, high-speed superhard material grinding wheels, imported high-end 5-axis linkage and other CNC grinding machines Just can't be applied, etc., the application of diamond grinding wheel and various products in the high-tech field is too numerous to enumerate.

All developed countries in the world focus on the development of diamond grinding wheels and products. It can be said that the research and application of superhard materials and products represent a country's technological development level. Some scientists say that the 21st century will be the century of diamond grinding wheels. In particular, special-shaped electroplated grinding wheels are widely used.

.png)